Our Services

Always In Stock Styles

We also offer over 120 additional styles to suit your unique needs. Contact us to learn more!

Dalmatian

Pebble Gray

Volcanic Gray

Graystoke

Lakeshore

Streambed

Starlight

Wilderness

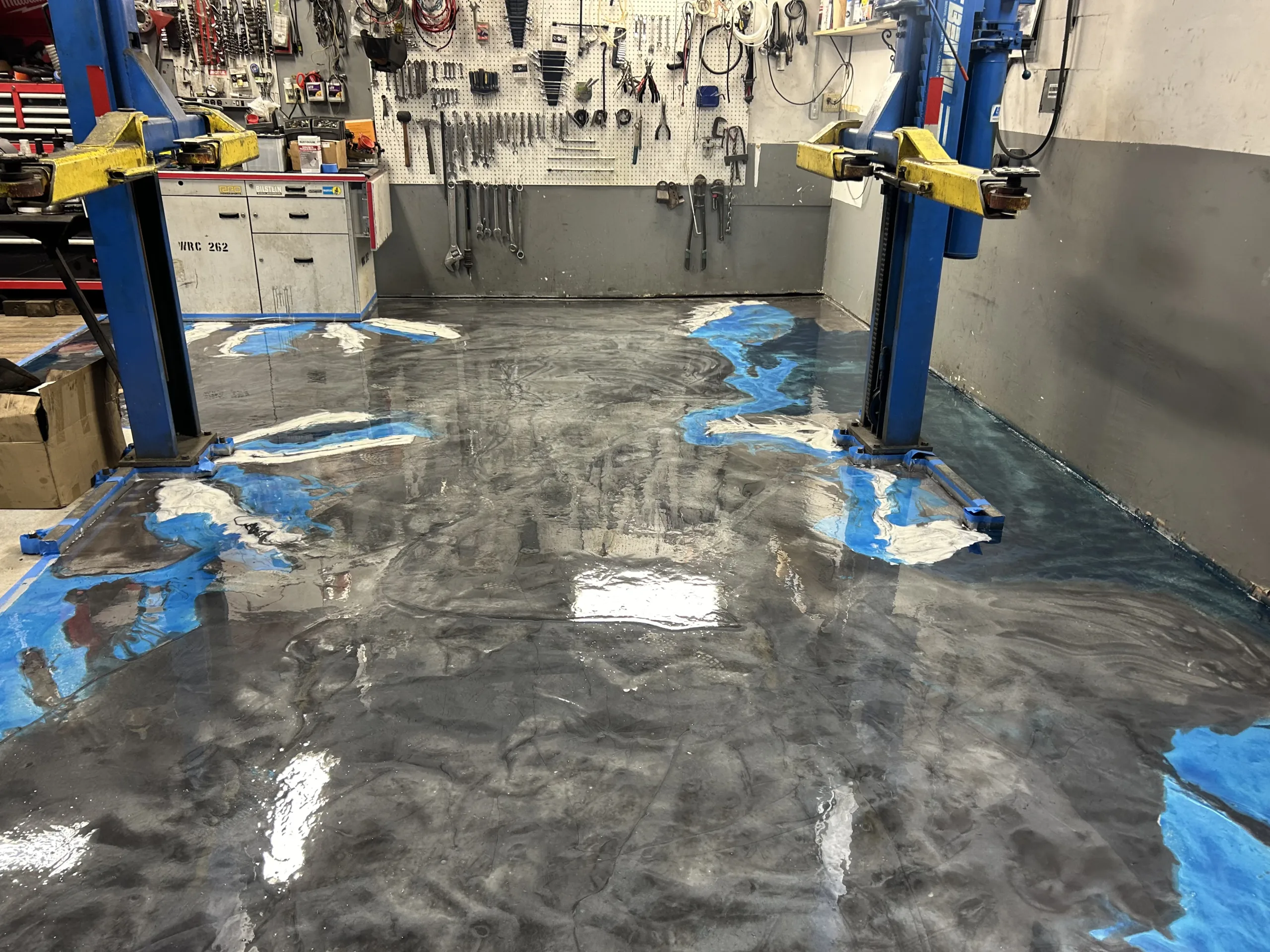

Antislip

Matte

Metallic

Super Gloss

Our Process

Bringing you closer to the floor you’ve always wanted.

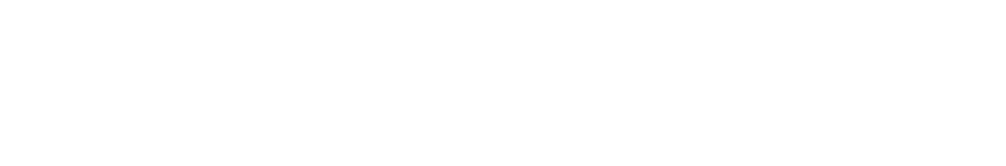

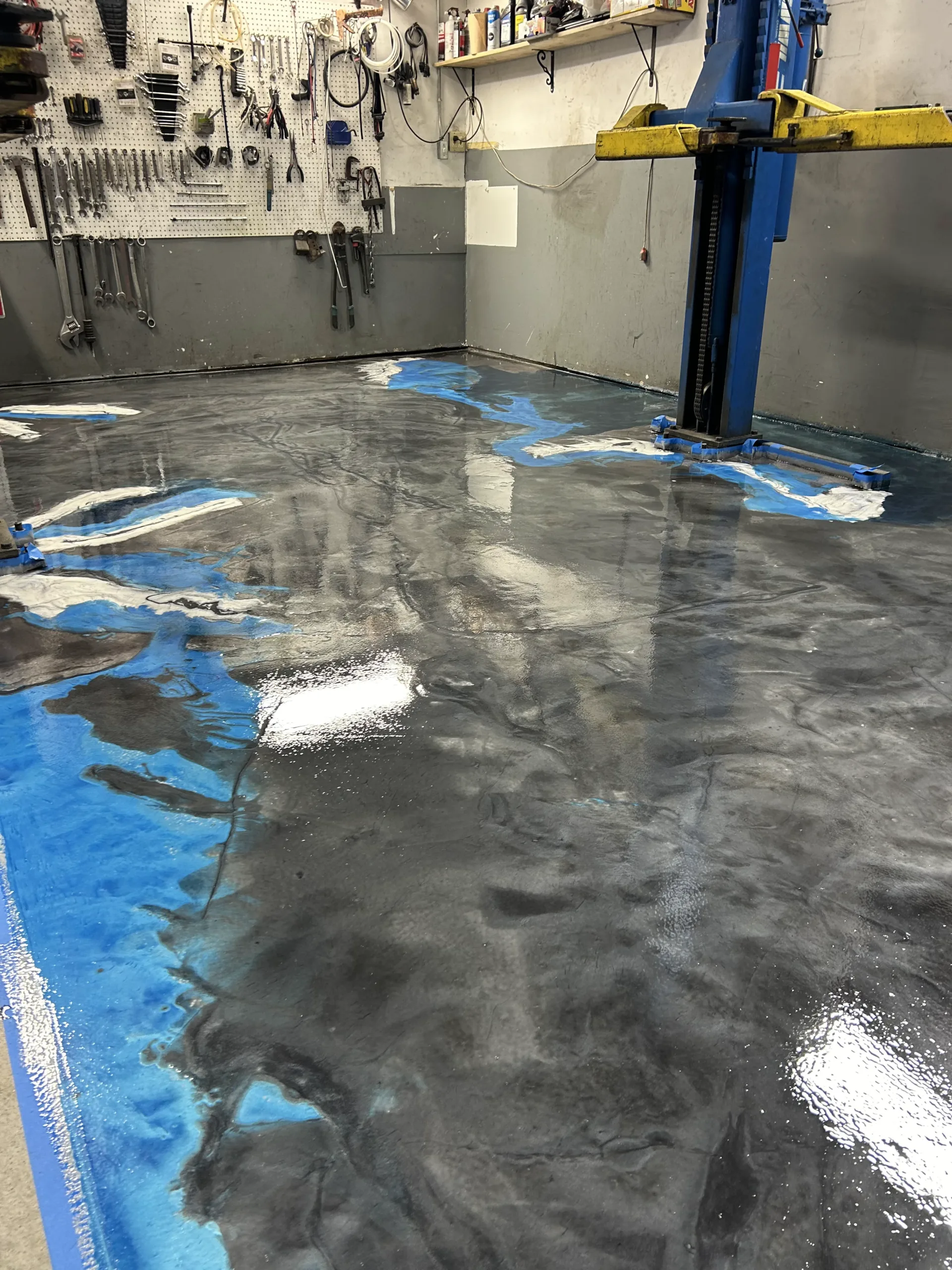

Our Projects

Visual Elegance: A Gallery of Possibilities

From sleek and modern garage floor epoxies to elegant and unique metallic designs for living spaces, our gallery showcases the versatility and beauty of epoxy flooring.

Let’s work on your project together

Special Offer: Free Epoxy Baseboards

For projects over 1000 sq ft, we are offering free epoxy baseboards. Enhance the durability and aesthetic appeal of your space with seamless, high-quality epoxy flooring and complimentary baseboards, ensuring a complete and polished look.

Guaranteed Accountability

We deliver results

300+

Satisfied Customers

“I recently had my garage floor done by TRIAD FLOORING-NW, and I’m absolutely thrilled with the results! The team was professional, punctual, and the quality of work is top-notch. My garage looks like a showroom now. Highly recommend!”

Amanda G., Seattle

5,000+

Square Feet of Flooring Installed Monthly

“I was looking to someone able to cover some old tiles with epoxy in a commercial kitchen.

They answered fast, plan and execute the job as planned and accommodating my schedule.

They went above and beyond to make me happy and satisfied with the final result and the whole process was smooth.

Really professional and definitely worth the price!

Recommended 1000%!!!”

Giovanni C. Lynnwood

10-Year

Durability Guarantee

“Very happy with our new epoxy flake flooring! From the initial quote to the complete installation, the entire process took less than a week. The Triad Flooring team was highly professional, providing excellent communication throughout, and even made sure everything was clean before they left. I’m thoroughly impressed with their quality, speed and cost. Highly recommend for anyone looking for flooring services!”

Artur G. Newcastle